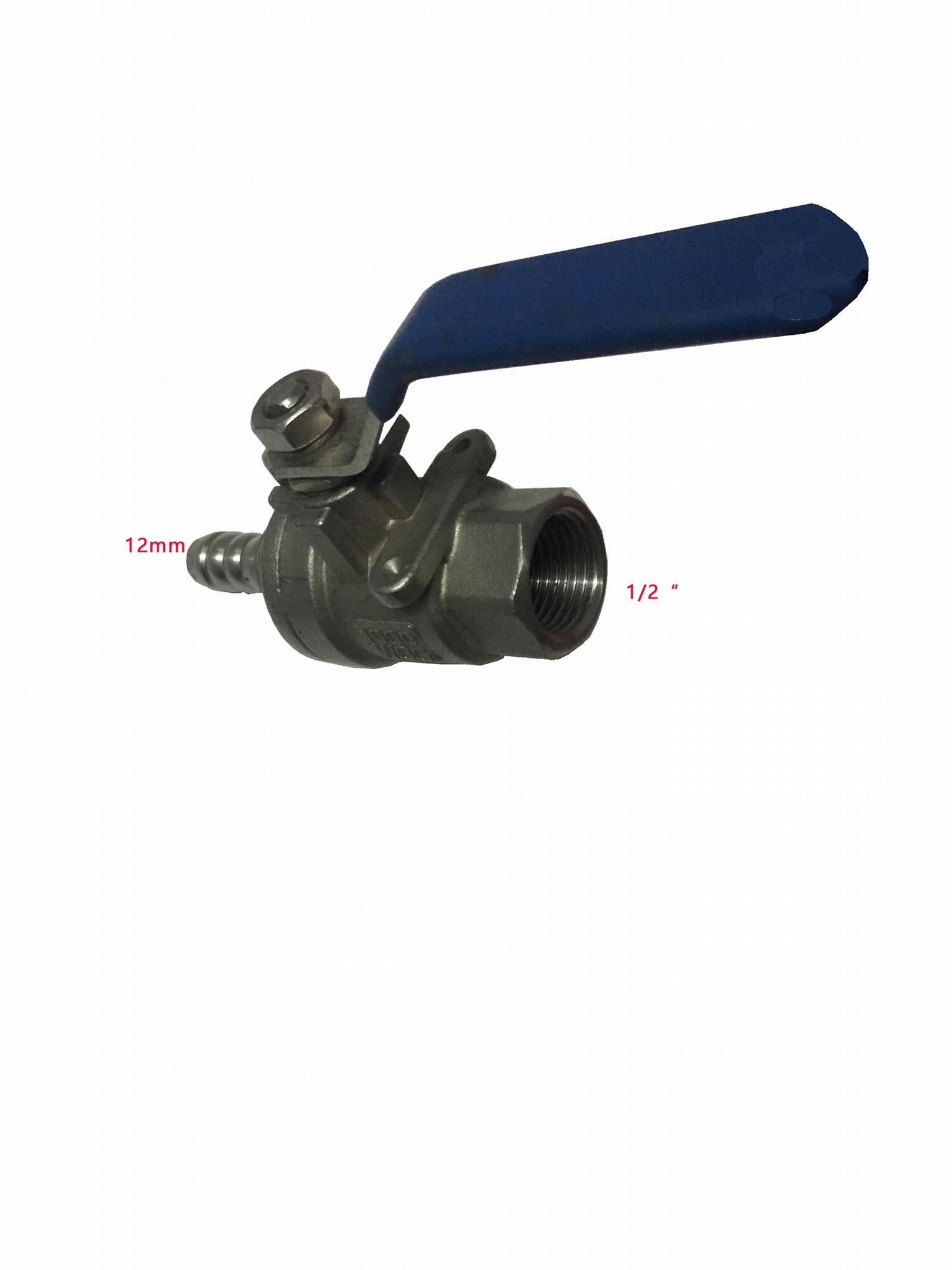

Model No.︰天然气一体宝塔球阀

Brand Name︰MY DREAM

Country of Origin︰-

Unit Price︰CNY ¥ 28 / pc

Minimum Order︰1 pc

Stainless steel two-piece integrated pagoda ball valve is a common type of ball valve with the following characteristics and functions:

Corrosion resistance and high-pressure fluid control: Made of stainless steel material (such as 304/316), it can resist acid, alkali, salt corrosion, and is suitable for corrosive media such as chemical and petroleum industries and high-pressure pipeline systems.

Fast opening and closing and flow regulation: By rotating 90 ° through pneumatic drive, the medium flow can be quickly cut off or connected, with both throttling and flow control functions, meeting the needs of industrial automation.

Compact structure and convenient maintenance: The two-piece valve body is connected by threads or bolts, and can be disassembled without damaging the pipeline, simplifying the installation process and adapting to space limited pipeline layouts.

Industrial automation adaptation: compatible with air source pressure control (0.4~0.7MPa) and solenoid valve linkage, supports remote operation and status feedback, and can be integrated into automation systems such as PLC.

Sealing performance: The medium pressure pushes the ball to tightly adhere to the PTFE (F4) valve seat, forming a self tight seal to ensure no leakage under high pressure.

Application scenarios

Stainless steel two-piece integrated pagoda ball valve is widely used in the following fields:

Chemical high-pressure corrosive medium transportation: suitable for the chemical industry, capable of withstanding high pressure and corrosive media.

Oil and gas pipelines: used in oil and gas transportation systems to ensure the safety and efficiency of fluid control.

Pharmaceutical equipment: used in the pharmaceutical industry for automated systems that are corrosion-resistant, pressure resistant, and frequently open and close.

Maintenance and upkeep suggestions

To ensure the long-term stable operation of the stainless steel two-piece integrated pagoda ball valve, it is recommended to regularly perform the following maintenance and upkeep:

Regularly check the seals: ensure that the seals are not worn or aged, and replace damaged seals in a timely manner.

Cleaning the interior of the valve body: Regularly clean the interior of the valve body to prevent impurities from accumulating and affecting valve performance.

Lubricate the valve stem: Regularly lubricate the valve stem to ensure smooth rotation.

Check the pneumatic actuator: Ensure that the pneumatic actuator is working properly and the air pressure is stable.

Payment Terms︰ TT/LC